Why Southern and Traditional Homes? (10 Extra Steps)

Our company began with the simple goal of constructing the best homes possible. With the same principles of fine automakers, we know that quality is appreciated and noticed. Unlike the fine automakers, we do all of this with very competitive pricing. Whether a starter home or a finely appointed custom home, we incorporate the same construction techniques. You have our commitment that we will NEVER compromise quality. Listed below are just 10 of the many reasons to choose Southern and Traditional Homes.

(Click on the Pictures to Enlarge and then the Back Button to return.)

|

A 14-ton vibrating roller is used to compact the virgin soil and first one foot lift prior to placing the footer. This ensures maximum compaction for construction. Proper compaction is esential to the soundness of your home. This is commercial quality for a residential application. |

|

Our one-story footers are designed to have twice the strength of that required by the Florida Building Code. We use 10" x 20" footers with 3 - #5 rebar and use nothing less than 3000 psi concrete. The extra strength in the footer helps to minimize cracking in both the footer and the walls. |

|

Using the proper soil is necessary to obtain the proper compaction. Soil composition must contain the correct levels of both moisture and clay to achieve the maximum compactions. If the fill dirt isn't right, we send it back. |

|

S & T Homes continues to use wire mesh to reinforce their concrete, even after most builders have replaced it with fiber mesh. Fiber mesh is a cost saving measure which leaves the concrete unsupported after cracking. Our concrete is placed and not poured using a 5" slump. The less water in the concrete the fewer cracks. |

|

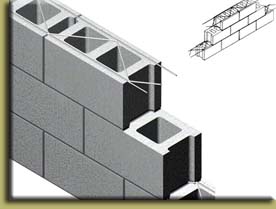

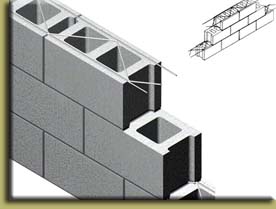

Every other row of block is reinforced horizontally to prevent stairstep cracks in the block. This again is a commercial application for residential construction and not required by the county. This step, combined with the previous steps, creates one of the strongest shell structures available in Hillsborough County. |

|

Once the block work is complete, we use a Drylock waterproof coating around the windows to prevent water from wicking in behind your drywall. If the paint or stucco coating cracks at the window sill, this step helps guard against water intrusion. |

|

S & T Homes places a 10 x 24 storage unit on the property before the first lumber delivery. When the lumber is delivered, it is handstacked in the container to guard it from the rain and the sun. Excessive moisture can cause swelling and mold, and the sun can cause severe warping of the wood. |

|

We use Owens Corning Foamular wall insulation as opposed to the minimum standard foil paper. The foam insulation protects much better and lasts long after the paper and foil have deteriorated. It also is an additional layer of protection against water intrusion, keeping moisture from the drywall. |

|

Huber's Zip Roofing System is now used exclusively for all of our roofing. It provides 30 years of waterproofing and is a secondary layer of protection against water intrusion. Additionally, our roof sheathing isn't damaged by rains during the construction process. Ordinary sheathing becomes delaminated and swells after just one rain event. |

|

Tile underlayment is installed under all tile areas to prevent future cracks. We have never had a warranty call for cracked tiles! This floor is a remodeling project which required floating, covering an expansion joint, and new plumbing cuts in the floor. The underlayment on the right will prevent future tile cracks.

|

We know of no other builder that takes these extra steps to ensure the long lasting quality of your home! In a day and age when cost cutting measures dictate the finished quality of your home, it is refreshing to find a builder that refuses to do so.